The Problem:

Current nano-machining technology utilizes only a plowing action for cutting where the tool is forced into the surface to be shaped and uses bending to provide the force to the cutting tip. The current technology only allows for thin grooves and requires an indentation into the surface. There is a need for technology with increased accuracy to speed up the overall machining process and potentially reduce number of necessary adjustments.

The Solution:

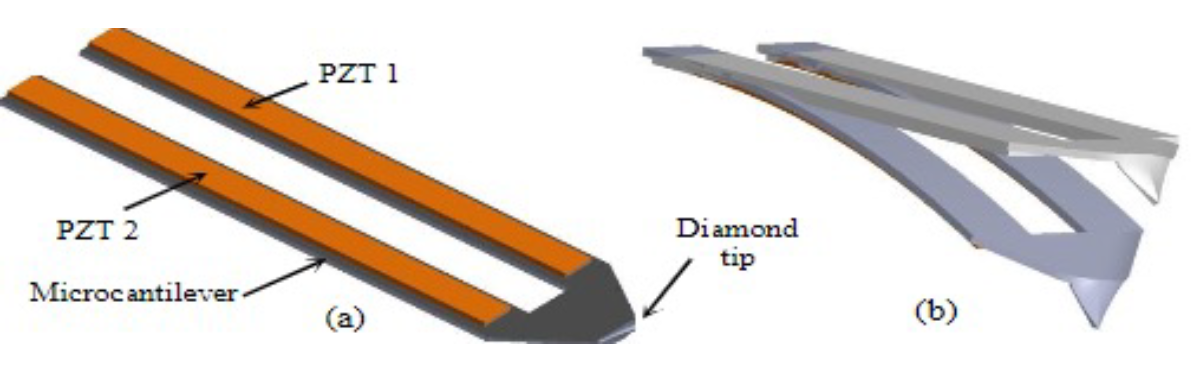

Researchers at the University of Alabama have developed a tool for machining (cutting and shaping) and manufacturing surfaces at the nano-scale level using atomic force microscopes. This technology is useful in the areas of three-dimensional (3-D) manufacturing of carbon nano-tube based computer circuits and dissection of nano-scale biological objects such as DNA. The tool consists of a double-armed micro-cantilever with a diamond cutting tip, and each of the two arms are enhanced with a piezoelectric layer which allows a controllable vibration in the tool improving cutting accuracy and decreasing the amount of force currently required for nano-machining.

Schematic Representation of Dynamic Sweep-Plow Microcantilever

Schematic Representation of Dynamic Sweep-Plow Microcantilever

Benefits:

• Torsional as well as bending forces applied to cutting head. (industry first)

• Allows for wider cutting grooves.

• Allows for cutting without indentation or cutting of the surface.

• Decreases time required for machining process.

• Increases accuracy and control over cutting head.

• Reduces the number of adjustments needed.

The University of Alabama Research Office of Innovation and Commercialization (OIC) is a non-profit corporation that is responsible for commercializing University of Alabama technologies and for supporting University research. At OIC, we seek parties that are interested in learning more about our technologies and commercialization opportunities, and we welcome any inquiries you may have.