The Problem:

Powder-based electron beam additive manufacturing (EBAM) utilizes a high-energy electron beam, as a moving heat source, to melt and fuse metallic powders and produce parts in a layer-wise fashion. If a part has overhang geometry, such as a cantilevered overhang or undercut portion, defects such as curling may occur due to the thermal gradient cycles that lead to high thermal stresses and geometric deformation. Current practices for encountering curling are laborious, time consuming, and degrade the surface quality of the cantilevered portion.

The Solution:

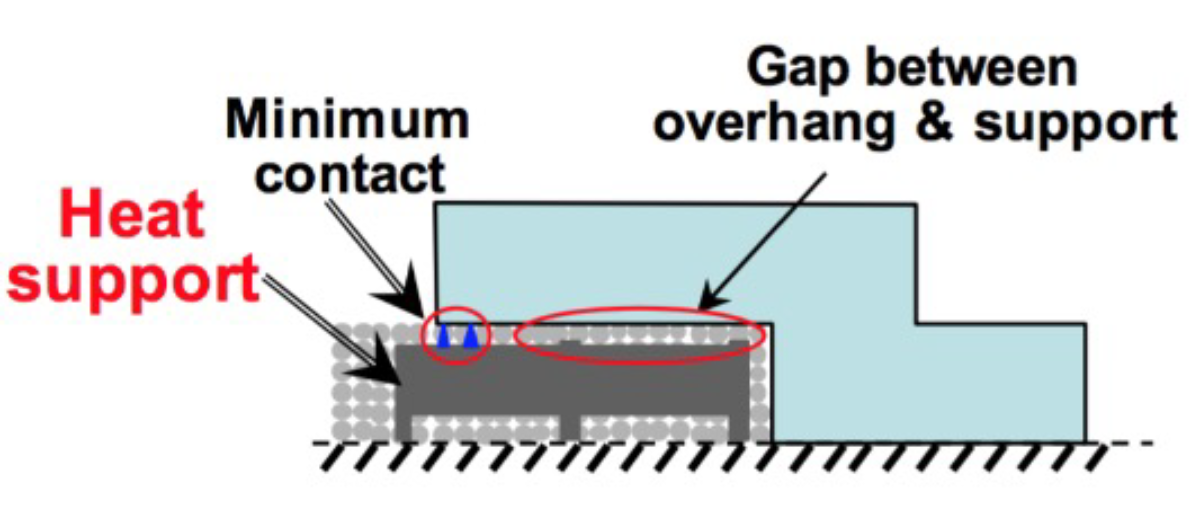

Researchers at the University of Alabama have developed a concept of designing and fabricating a minimum contact “heat support” structure when fabricating a part with overhangs (or down-facing features) using powder-bed fusion metal additive manufacturing. This invention is an improved manufacturing process to reduce distortion in fabrication and reduce the post processing time to help keep the metal from defecting during metal additive manufacturing.

Model of Invention

Model of Invention

Benefits:

• Reduce distortion in fabrication.

• Reduce manufacturing time.

• Possible use in plastic manufacturing as well.

• Maintains structural integrity in overhang areas.

• No/minimum contact between the overhang and the heat support: prevents overhang from distortions and reduces the need of removing support structures.

• Process performance enhancement, support design simplicity, and overhang structural integrity.

The University of Alabama Research Office of Innovation and Commercialization (OIC) is a non-profit corporation that is responsible for commercializing University of Alabama technologies and for supporting University research. At OIC, we seek parties that are interested in learning more about our technologies and commercialization opportunities, and we welcome any inquiries you may have.