The Problem:

Chemical Looping Reactions (CLRs) are advantageous in the energy industry due to the desirable ability to recycle gases in energy production processes. Current chemical looping reactions are capable of achieving carbon capture sequestration (CCS); however, they cannot do so at low, desirable temperatures. Additionally, attempts to perform CLRs at lower temperatures have not produced high yields, which is inefficient.

The Solution:

The invention is a process that applies low power non-equilibrium plasma on nano-catalysts to create CLRs. The temperature threshold is effectively lowered to create the CLR. Additionally, because the temperature is much lower than traditional processes, a high yield is able to be obtained and energy costs are lowered to perform the process.

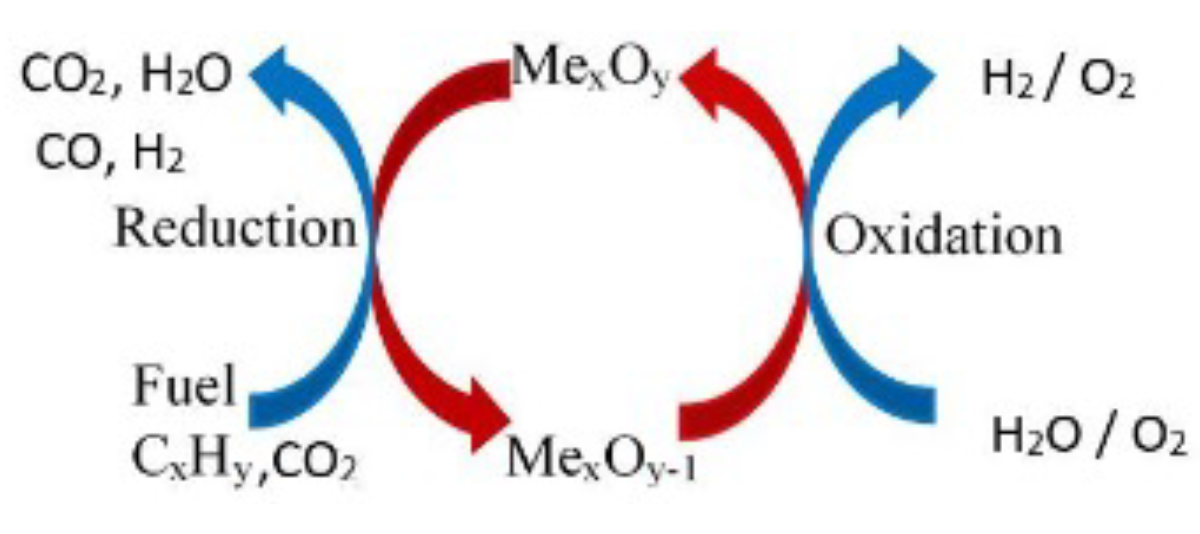

Chemical looping reforming process.

Chemical looping reforming process.

Benefits:

• Achieves CLRs at low temperatures

• Can use waste heat, including solar and wind energy

• Low cost and economical

• Ease of reactor construction (easier to seal reactors exposed to lower temperatures)

The University of Alabama Office for Innovation and Commercialization(OIC) is a non-profit corporation that is responsible for commercializing University of Alabama technologies and for supporting University research. At OIC, we seek parties that are interested in learning more about our technologies and commercialization opportunities, and we welcome any inquiries you may have.