The Problem:

Cold spray deposition is used in a variety of industries for corrosion-prevention coatings. The majority of feedstock powder for cold spray deposition is made through rapid solidification methods (such as gas atomization) which produce powders possessing microstructures distinctly different from the desirable microstructure found in wrought material forms. The deleterious characteristic of the powder microstructure is a network of intermetallics that cause several problems, including limited deposition efficiency (the fraction of powder that sticks to the substrate), degraded corrosion resistance, and limited strength in the as-sprayed condition.

The Solution:

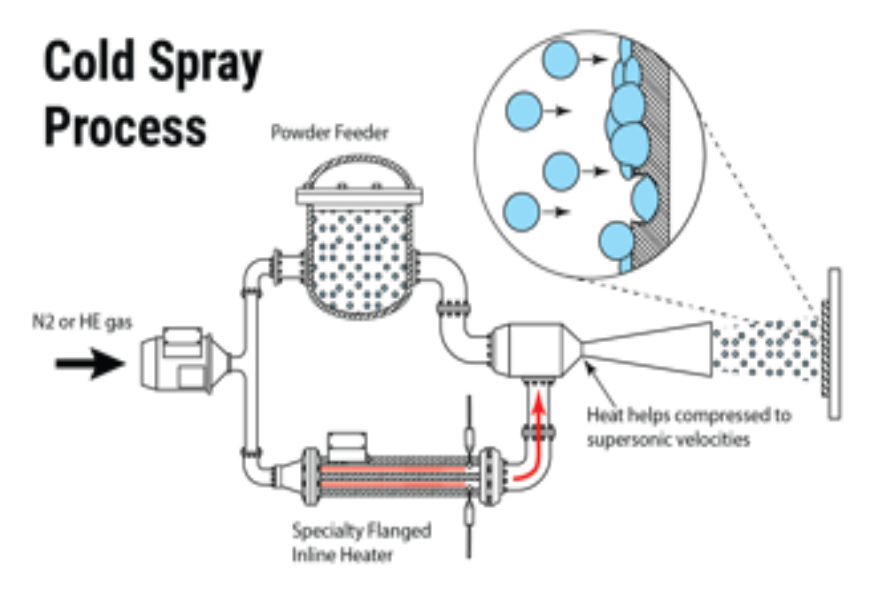

Researchers at the University of Alabama have developed a process that enhances the characteristics of feedstock powder for cold gas dynamic spray deposition, also known as "cold spray". The invention described here uses a two step heating treating process to dissolve this network of intermetallics. In this newly invented process, the metallic powder is heated in an inert environment to a temperature sufficient to dissolve, or solutionize, the intermetallics. After solutionizing, the powder is rapidly quenched to avoid the reformation of the intermetallics during cooling.

Benefits:

• Reduction in intermetallic density

• 35-60% increase in deposition efficiency of spray

• Enhanced corrosion resistance, achievable strength, and ductility in deposited material

The University of Alabama Research Office of Innovation and Commercialization (OIC) is a non-profit corporation that is responsible for commercializing University of Alabama technologies and for supporting University research. At OIC, we seek parties that are interested in learning more about our technologies and commercialization opportunities, and we welcome any inquiries you may have.